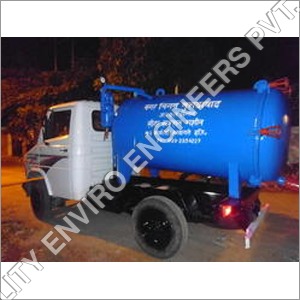

Sewer Suction Cum Jetting Machine

Price 5800000 INR/ Unit

Sewer Suction Cum Jetting Machine Specification

- Accessories

- Jetting Hoses, Suction Hoses, Nozzle Kit, Control Panel

- Control System

- Manual & Hydraulic Control

- Features

- Combined Jetting and Suction, High Durability, Heavy Duty Construction, Customizable Tank Size

- Suction Power

- Vacuum Generation up to 8000 mm WG

- Equipment Type

- Sewer Suction Cum Jetting Machine

- Connectivity Type

- Hose Connection with Nozzles

- Tank Capacity

- 5000~7000 Litres (Customizable)

- Pressure Ratings

- 120 to 200 Bar (Jetting Pump)

- Power Source

- Vehicle Engine Driven Hydraulic System

- Water Flow Rate

- 120 to 250 LPM (Litres Per Minute)

- Material

- Mild Steel (MS)

- Type

- Truck Mounted

- Condition

- New

- Fuel Type

- Diesel

- Use

- Sewer Cleaning and Maintenance

- Cleaning Process

- High Pressure Jetting & Suction

- Cleaning Type

- Industrial / Municipal

- Capacity

- Up to 7000 Litres

- Voltage

- 24V DC (Truck Battery Operated)

- Painting

- Corrosion Resistant Epoxy Coating

- Chassis Required

- Heavy Truck Chassis (Suitable for 16T GVW or more)

- Operation Mode

- On-Board Engine or PTO Driven

- Safety System

- Pressure Relief Valve & Emergency Stop

- Suction Hose Diameter

- 4"/6" (100-150 mm)

- Pump Type

- Triplex Plunger Pump

- Standards Compliance

- IS: 2433 / BS EN 1829

- Mobility

- Self-propelled with Truck Chassis

- Discharge System

- Hydraulic Tipping/Discharge

- Jetting Hose Length

- 60~100 meters

- Nozzle Type

- Multiple Jetting Nozzles (Penetrating, Rotating, Flushing)

- Ambient Temperature Range

- -10°C to 50°C

Sewer Suction Cum Jetting Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Paypal, Cash in Advance (CID), Cheque

- Supply Ability

- Unit

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About Sewer Suction Cum Jetting Machine

We are the leading manufacturers of Sewer Suction Cum Jetting Machine.

The equipment consists of suction and a high-pressure water jetting equipment integrated to complete the Suction-cum-Jetting Combination unit.

Specification

| Tank Material | Mild Steel |

| Model | QEEBI- 8LCH |

| Capacity | 500- 15000 Ltr |

| Automation Grade | Semi Automatic |

| Diameter | 4 Feet -36 Feet |

| Dia Of Desalting Manhole | 250-12000 mm |

| Suction Hose Length | 15Mtr |

| Power Source | Vehicle Engine |

All-in-One Sewer Cleaning Solution

This machine streamlines sewer cleaning by merging high-pressure jetting and strong suction in one truck-mounted unit. It efficiently dislodges and removes blockages, sludge, and debris-even in the most demanding urban and industrial settings. Designed for heavy use, the system is equipped with rugged components, enhancing reliability and performance during critical municipal operations.

Superior Durability and Customization

Manufactured with mild steel and shielded by a corrosion-resistant epoxy coating, the machine is built to withstand harsh environments. With customizable tank capacities and a wide range of accessories, users can tailor the equipment to specific operational requirements. This flexibility ensures suitability, whether for large-scale city projects or targeted industrial maintenance.

User-Friendly Operation and Enhanced Safety

The unit operates through a vehicle engine-driven hydraulic system, offering manual and hydraulic controls accessible via an onboard panel. Critical safety features, such as a pressure relief valve and emergency stop, are integrated to protect both the operator and equipment, while adhering to stringent IS: 2433 and BS EN 1829 standards.

FAQ's of Sewer Suction Cum Jetting Machine:

Q: How does the sewer suction cum jetting machine operate?

A: This equipment utilizes a vehicle-mounted hydraulic system powered by the truck's engine, combining high-pressure water jetting with powerful suction. The operator uses manual and hydraulic controls to maneuver jetting and suction hoses, dislodging and evacuating blockages from sewer lines.Q: What types of nozzles are included and what are their functions?

A: The machine comes with multiple jetting nozzles-penetrating, rotating, and flushing. Penetrating nozzles break through tough clogs, rotating nozzles clean pipe walls, and flushing nozzles wash away loosened debris, ensuring comprehensive cleaning.Q: Where can this machine be deployed and who typically uses it?

A: Designed for municipal and industrial use, this machine is ideal for city sewer departments, service providers, and facilities needing high-capacity sewer cleaning. It is suited for roads, municipal drains, industrial premises, and residential neighborhoods.Q: What safety features are integrated into the machine?

A: To ensure safe operation, the system includes a pressure relief valve to prevent over-pressurization and an emergency stop mechanism to halt operations instantly if needed. These features safeguard both operators and equipment during use.Q: What is the cleaning process using this equipment?

A: The process involves inserting the jetting hose into the clogged sewer, activating high-pressure water to dislodge obstructions, and using suction to extract debris into the tank. The hydraulic discharge system enables easy and hygienic emptying of collected waste.Q: When should regular maintenance be carried out for optimum performance?

A: Routine maintenance is recommended after each major use or as outlined in the manufacturer's guidelines. Periodic inspection and servicing of hoses, pumps, valves, and controls ensure longevity and reliable operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sewer Suction Machine Category

Sewer Suction Machine

Price 250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Stainless Steel

Type : Other, Truck Mounted

Condition : New

Features : Heavy Duty, Corrosion Resistant, Automated Discharge

Mobile Sewer Cleaning Machine

Price 5100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel

Type : Other, Sewer Cleaning Machine

Condition : New

Features : Heavy Duty, Corrosion Resistant, Robust Wheels, Easy to Operate

Bucket Type Sewer Cleaning Machine

Price 600000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Heavy Duty Mild Steel

Type : Other, Bucket Type

Condition : New

Features : Robust bucket mechanism, Corrosionresistant construction, Mounted on vehicle chassis

Chasis Mounted Sewer Suction Machine

Price 255000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Mild steel tank body

Type : Other, Chassis mounted

Condition : New

Features : High suction capacity durable tank easy maneuverability

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free